Your Switchgear’s Intelligent “Doctor” – Foresee Risks, Ensure Safety

The operational health of switchgear directly impacts power supply continuity and system safety. Traditional periodic maintenance and manual inspection methods have inherent blind spots, making it difficult to detect hidden risks such as internal overheating, insulation degradation, and environmental abnormalities in a timely manner, which can lead to unexpected failures. To address this challenge, we introduce a professional Switchgear Online Condition Monitoring System.

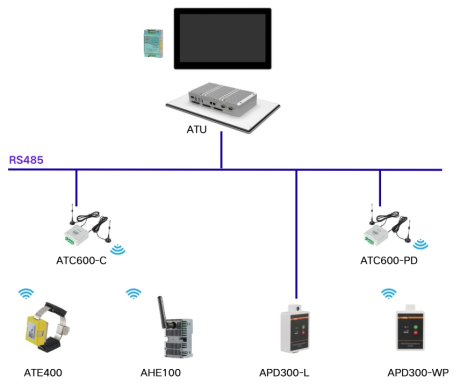

This comprehensive solution integrating temperature, humidity, partial discharge, arc flash, and power quality monitoring,continuously collect and analyze key internal conditions of the switchgear.

It facilitates a fundamental shift from "reactive repair" and "periodic maintenance" to "proactive warning" and "predictive maintenance," providing you with a comprehensive and proactive equipment health management solution.

Professionalism: Designed based on switchgear failure mechanisms, covering all core risk points.

Predictive Capability: Early detection of fault signs, avoiding unplanned downtime and catastrophic failures.

Intelligence: Real-time data upload to cloud platforms or local system, supporting trend analysis and remote alerts.

![]() Comprehensive Temperature Monitoring

Comprehensive Temperature Monitoring

Targets: All critical connection points including busbar joints, circuit breaker contacts, and cable terminals.

Solves: Precisely locates overheating points caused by poor contact, preventing electrical fires and connection failures.

Core Value: Enables early overheating warning and guides preventive maintenance based on real-time temperature and trend analysis.

Core Product:

ATE400 Wireless Temperature Sensor

Employs high-precision sensing and wireless passive technology, installed directly on Low, Medium, High-voltage live parts for safe, reliable, and maintenance-free long-term online temperature monitoring.

![]() Precision Partial Discharge Detection

Precision Partial Discharge Detection

Targets: Internal insulation components, busbar insulation, cable terminations.

Solves: Detects the earliest signals of insulation degradation, providing ample warning time before failures occur.

Core Value: Identifies discharge types and patterns, quantifies insulation health status, serving as the core basis for condition-based maintenance.

Core Product:

APD300 Series Partial Discharge Sensor

Offers AE, TEV and UHF detection methods to accurately capture and locate internal PD activity, assessing insulation health status.

![]() Arc Flash Safety Protection

Arc Flash Safety Protection

Targets: Sudden arc flash faults inside the cabinet.

Solves: Acts as the last line of defense, detecting and suppressing highly destructive arc flash faults within milliseconds.

Core Value: Millisecond-level rapid response minimizes fault energy impact, protecting equipment and personnel.

Core Product:

ARB6 Arc Flash Protection Relay

Based on high-speed light detection and current criteria, offers extremely fast operation (≤

7.8ms), providing vital transient fault protection for critical switchgear.

![]() Intelligent Cabinet Environment Management

Intelligent Cabinet Environment Management

Targets: Internal temperature, humidity status.

Solves: Proactively prevents insulation degradation and flashover faults caused by excessive humidity or temperature.

Core Value: Temperature and humidity monitoring effectively protects internal components and extends their service life..

Core Product:

AHE100 Temperature and Humidity Sensor

Specifically designed to monitor temperature and humidity inside switchgear in real-time, to promptly issue warnings for abnormal conditions risks.

![]() Power Quality & Load Analysis

Power Quality & Load Analysis

Targets: Voltage, current, power, harmonics, three-phase imbalance, etc.

Solves: Provides in-depth understanding of power supply quality and actual load, identifying potential power quality issues.

Core Value: Provides key data support for load optimization, energy efficiency management, and root-cause fault analysis.

Core Product:

APView500 Power Quality Analyzer

A high-performance embedded platform that enables comprehensive power quality parameter monitoring, event recording, and energy efficiency analysis, supporting refined management decisions.

· Power Grid Companies: Smart retrofitting and condition management of 10/35kV switchgear and ring main units in substations.

· Industrial Users: Main distribution rooms and critical process segment switchgear in industries like petrochemicals, steel, semiconductors, and automotive manufacturing to ensure continuous production.

· Data Centers: Provides reliability warnings for critical power infrastructure (MV distribution, UPS input/output cabinets).

· Public Transportation: Traction substations and distribution stations in subways and airports, enhancing power supply safety for public facilities.

· Commercial Buildings: Power distribution centers in large complexes, hospitals, and schools, enabling intelligent operation and management.

Make Safety Visible, Make O&M Smart

Contact us today for a customized monitoring solution and system demonstration.

Kindly Fill out the Form below and tell us more about your Requirements,

We would like to provide Suitable Solution for You.

or Send us Email directly, [email protected]

Kindly Fill out the Form below and tell us more about your Requirements,

We would like to provide Suitable Solution for You.

or Send us Email directly, [email protected]